Product Description

Rotor & Pad Installation Video

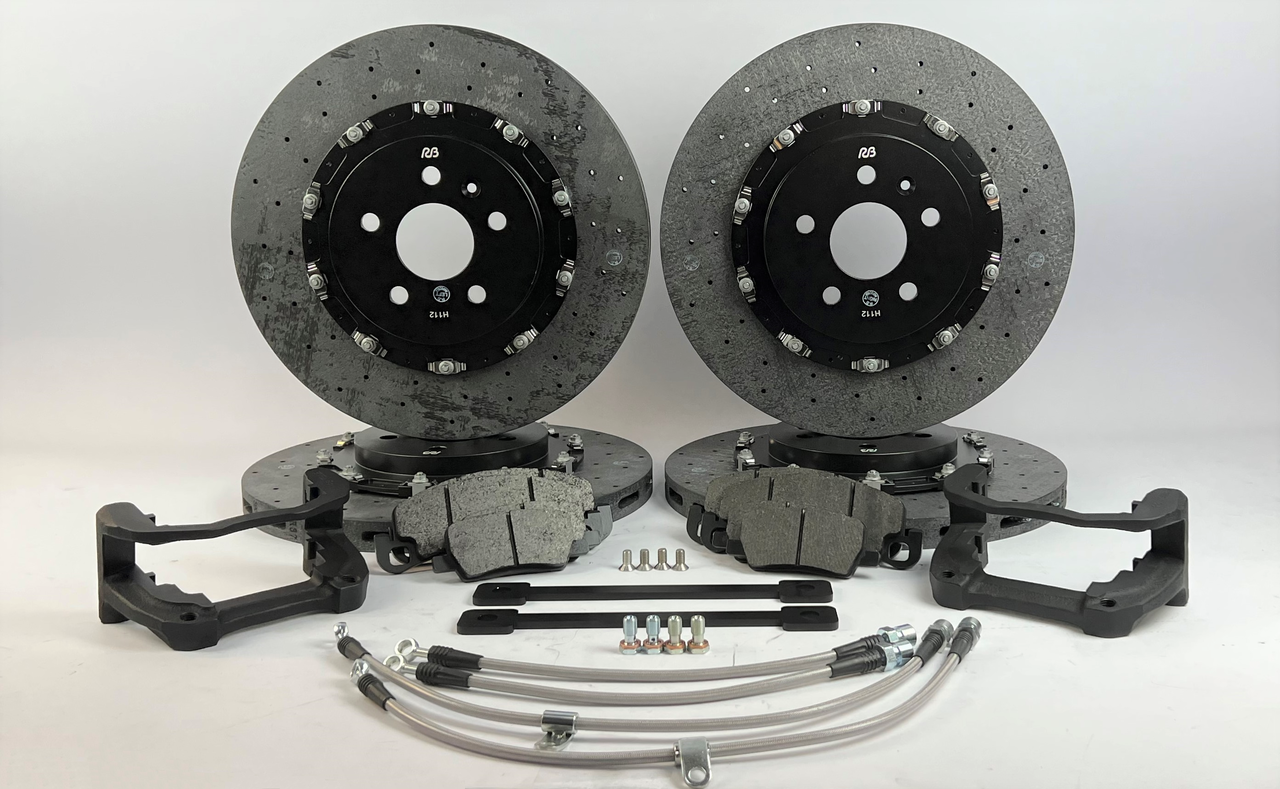

Kit includes:

- 2 ea front ccb rotors (410x33mm vs. OE 395x32mm)

- 1 set front OE caliper spacers & mounting hardware

- 2 ea rear ccb rotors (Stock size 365x28 or BBK 410x29mm)

- 1 set rear OE caliper bracket & mounting hardware (For BBK only)

- 1 car set brake pads made for CCB rotors (Larger front pad than OE)

- 1 car set rotor retaining screws

- 1 car set SS braided brake lines (optional)

Installation Note:

- This CCM rotor BBK is specially developed for Tesla X Plaid conversion upgrade from stock iron rotors.

- Rotors are made for an easy installation, and are 100% compatible with OE calipers.

- Requires 20" wheels with some trim on dust shield edges for larger rotors.

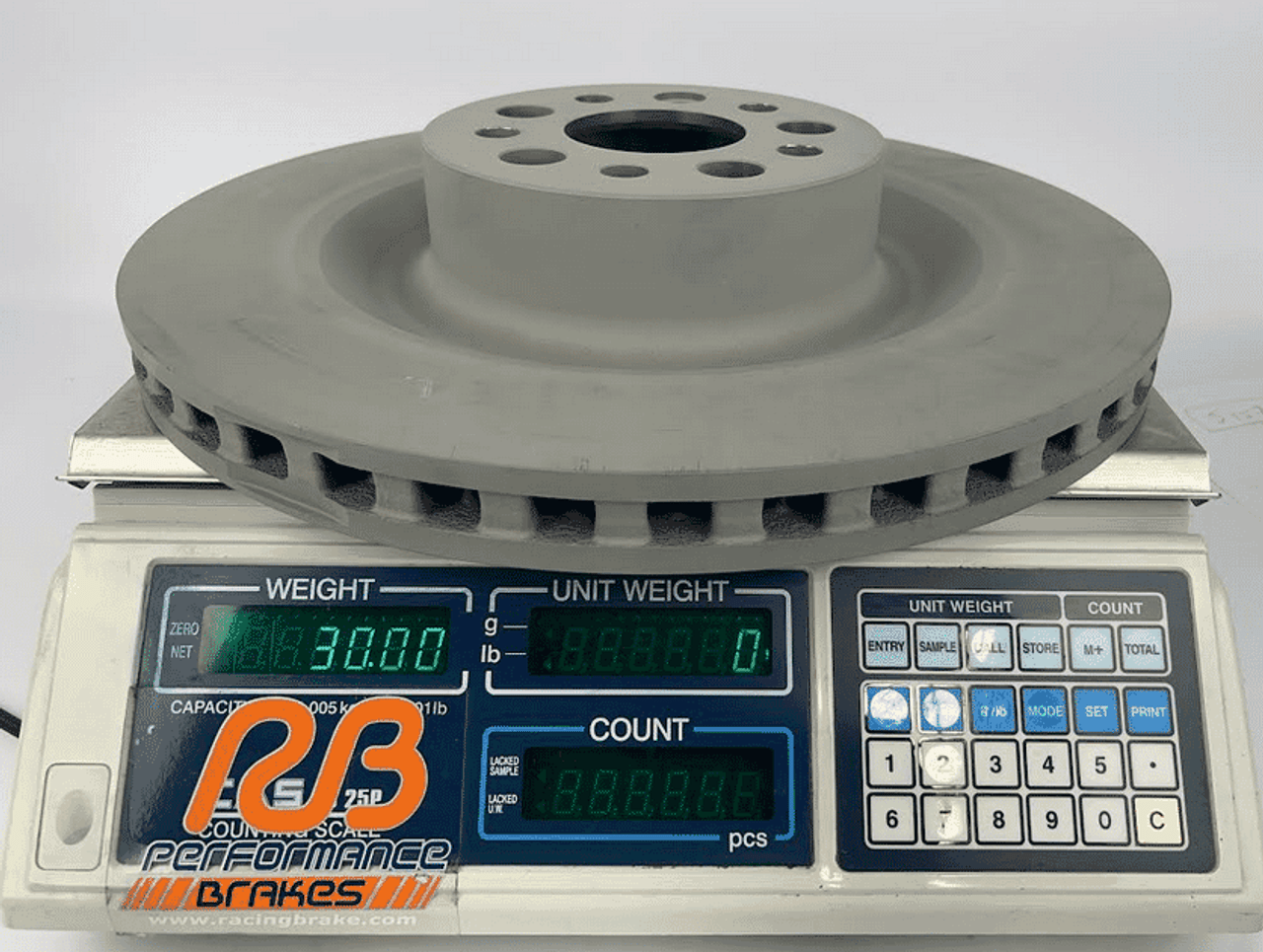

Weight saving table:

| ROTOR WT. COMPARISON (LBS) | FRONT | REAR | TOTAL/SIDE | TOTAL/CAR |

| OE IRON | 30 | 22.5 | 52.5 | 105 |

| RB CCM BBK* |

15 | 11.8 | 26.8 | 53.6 |

| WT SAVING |

15 |

10.7 |

25.7 |

51.4(49%) |

*Rear wt based on stock rotor 365x28mm

Feature & benefits:

- Easy bolt-on installation.

- All discs are made with RB Gen 4 CCM technology; long (continuous) carbon fibers and angle vanes.

- CCM rotors have "Diamond hard" surface with excellent "Thermal Stability" so they will NEVER Wear*, Warp, or Crack like conventional iron rotors due to the heat. More advantageous for tracking/racing with proper brake pads.

- Runs on street or tracks w/o temperature (cold or hot weather), or water (rain or car wash) effect.

- Never rust, always looks like new.

- Literally no brake dust.

- Dramatically reduction on unsprung weight.

- Improve driving comfort.

- Inspiring braking confidence on tracks.

- Substantial reduction on maintenance cost and downtime in pad and rotor replacements.

- Save money than iron brake in the long run.

Replacement components:

Brake pads: PD-plaid-cb

Compare RB rotor material - Continuous carbon fibers vs. OE/Brembo's chopped carbon fibers

In Cooling Vanes - Angle (directional) vs. Straight (Better cooling efficiency)

In Finish - Fully machined vs. as casted (Better look and balance)

To determine a CCM rotor serviceability, we recommend visual inspection by monitoring the rotor surface, than weight measurement suggested by OE/Brembo, which can be misleading w/o factoring in the weight of braking debris deposited in the drilled holes.

*If a CCM rotor is frequently running over the threshold temperature, the carbon will start oxidizing (losing carbon) resulting "pitted" surface which would act like a super grinder that can quickly wear out a new set of pad in just a few laps.

Avoid:

- Running rotor continuously above threshold temp @650F

- Running brake pad below 1/3 of the lining material (~4mm)

*The only wear out item of a CCM brake system is likely only the brake pad, stick to above golden rule and you will then have an almost forever brake system.