There are no products listed under this category.

- SELECT VEHICLE

- TECH INFO

- HOW TO CHECK WHEEL CLEARANCE

- HOW TO MEASURE A ROTOR OFFSET

Shop by Brand

TECH INFO & REFERENCE

RB makes brake pads primarily for our two piece rotors and brake kits only to assure the compatibility to our "harder" iron for optimal braking performance. Therefore these pads are listed under their respective two piece rotor/brake kit offer.

If you can't find the brake pad for your car in this "Brake Pad" category, chances are they are listed under our two piece rotor/brake kit section. Begin your selection from two piece rotor/brake kit, after you find the item, scroll down to the middle of the page and you will find them under "Replacement Components" where you can see the links for "Rotor Ring" and/or "Brake Pad".

Brake pad Selection Guide

Performance Street Compounds

The ET Series compounds provide excellent modulation, consistent friction and torque output, and can be run from ambient temperature, even during cold winter mornings.

ET500: Aggressive Street - Provides additional stopping power over ET300; low dust and little to no squeaking.

ET700-900: Advanced Street - For very adventurous street driving. Not for use on the track, as high temperatures will greatly accelerate pad wear. For track racing, use our XT-Series brake pads.

Motorsports Compounds

The XT Series compounds were developed to handle the toughest track braking conditions. All of our XT series can deliver consistent brake torque, are excellent in modulation and highly resistant to wear, friendly to rotors, brake dust is easy to clean, and brake control.

XT910: Medium initial bite, medium to high friction and brake torque.

XT960: Medium initial bite, high friction and brake torque.

XT970: High initial bite, extremely high friction and brake torque.

XR70: Track dedicated.

Since these pads are formulated for track/high temperature use, using them on the street may result some unfavorable situations such as brake squeal, dirty wheels, less brake friction at cold temperatures, and excessive rotor wear. For street driving, we recommended that you use our ET series pads.

Break-In

All brake pads are recommended to be bedded-in properly according to the proper break-in procedure to assure optimal performance.

Brake Pad Performance

The overall brake pad performance can be affected by the rotor material and its surface finish, calipers, and brake bias.

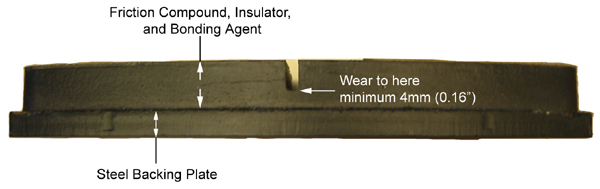

Since the brake pad consists of the friction material, insulator, bonding agent, and a steel plate, the pads must be replaced when the "non-steel" material wears down to approximately the same thickness as the steel back plate or to the grooves in the pad (if applicable). However, since the groove depth varies from one pad manufacturer to another, we do not recommend running the pad thinner than 4mm (0.16"). This minimum wear thickness is a checkpoint for pad replacement to prevent severe damage from occurring to the brake system, including rotors and calipers.

OE - Mercedes C63 Front pad cracked at the wear sensor slot

RB slots can alleviate the stress crack: