There are no products listed under this category.

- SELECT VEHICLE

- TECH INFO

- HOW TO CHECK WHEEL CLEARANCE

- HOW TO MEASURE A ROTOR OFFSET

Shop by Brand

TECH INFO.

WHY RacingBrake is your first choice on CCM Brakes?

Difference in Disc Material, Manufacturing Process, & Design:

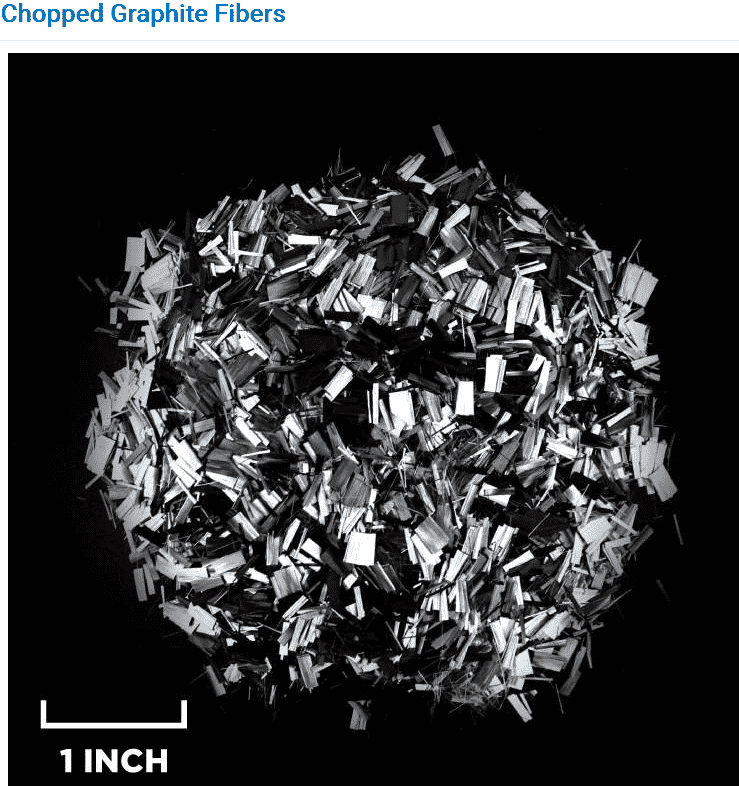

Brembo rotor made of Chopped carbon fiber (mixed with resin)

RB Discs are made of Woven (long) carbon fiber.

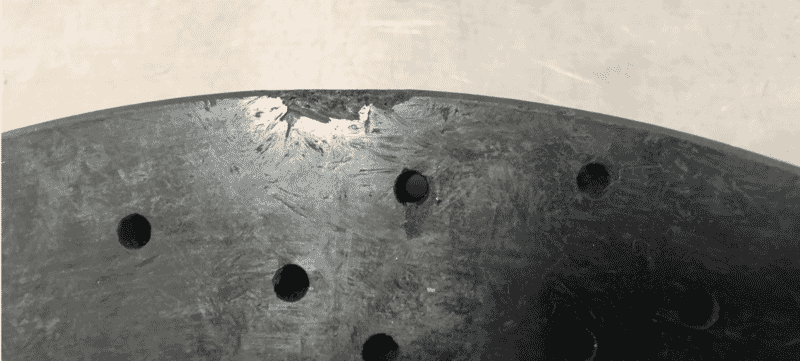

RB CCM Rotor with carbon fabric texture (Surface is actually very smooth.)

Here is a simple and easy to understand comparison between OE Brembo and RB disc material & construction.

Disc Design:

Straight cooling vanes (Left and right are the same)

Brembo & Surface Transforms

RB Angle vanes to improve cooling efficiency

Brembo Disc (OEM) - Chopped (Short) Carbon Fiber w/Straight cooling vanes:

Surface Transforms Disc - Continuous (Long) Carbon Fibers w/Straight cooling vanes

RB Disc - Continuous (Long) Carbon Fibers w/Angle cooling vanes, fully machined.

All hardware are designed and made. RB uses M6 Allen (vs. Brembo OE M5 w/H head) for extra strength and easy maintenance.

Rotor Hats:

RB hats are machined from forged 6061-T6 aluminum alloy (vs. extruded) for higher in strength and structure consistency.

Our hat design is programmed to generate "STEPS" to increase the heat path, which provides more cooling surface and extend the heat transfer time to the hub bearing from the disc - A True HAT that's more efficient in cooling, unlike competitions' design with a tapered contour "BELL" which has more immediate heat transfer with less cooling area.

ALL RB rotor hats are made with M4x0.7 thread holes for balancing provision even our individual disc is dynamically balanced with weight correction.

Competition's BELL:

.PNG?profile=-Watermark)